Filtration

Equipments

Equipped with proportional control valve, constant TMP operation can be realized.

Automatic water flux test.

Flow meter, conductivity meter, pH meter, UV detector can be equipped to record the curve in real time.

Perfect authority management, audit tracking and electronic signature, meets the requirements of 21 CFR Part 11.

| Names | ATFF 050 | ATFF 100 | ATFF 150 | ATFF 200 |

|---|---|---|---|---|

| Flow Rate | 50 L/min | 100 L/min | 150 L/min | 200 L/min |

| Membrane Area Max. | 5 m2 | 10 m2 | 15 m2 | 20 m2 |

| UV (optional) | 200~400 nm; Fixed single wavelengthor variable dual wavelengthes | |||

| pH (optional) | 0~14 | |||

| Conductivity (optional) | 0~300 mS/cm / 0~500 mS/cm | |||

| Flow Meters | Equipped at some ports according to user requirements | |||

| Control Modes | Constant TMP, constant pressure, constant flow rate, automatic water flux test | |||

| Operating Pressure Max. | 5 bar | |||

| Protection Class | IP65 | |||

| Software | Puriver™ | |||

Diaphragm pump provides power, low shear force and low pulse.

It can be equipped with storage tank and transfer pump, can control automatic transfer sample/buffer into the tank through liquid level gauge.

Constant flow rate and constant pressure control can be realized,pressure and TMP alarm can be set.

The design fully meets the requirements of GMP regulations and provides perfect IQ / OQ service.

| Names | STFF 01 | STFF 03 | STFF 10 | STFF 20 |

|---|---|---|---|---|

| Flow Rate | 0.05~1 L/min | 0.15~3 L/min | 0.5~10 L/min | 1~20 L/min |

| Pipe I.D.(mm) | 4 | 6 | 10 | 15 |

| pH (optional) | 0~14 | |||

| Conductivity (optional) | 0~300 mS/cm / 0~500 mS/cm | |||

| UV (optional) | 200~400 nm; Fixed single wavelengthor variable dual wavelengthes | |||

| Control Modes | Constant flow rate, constant pressure; pressure and TMP alarm can be set | |||

| Operating Pressure Max. | 5 bar | |||

| Software | Puriver™ | |||

Various types of single-use pump heads and flow paths are optional, which are delivered gamma-irradiated sterilization, can be used for different scales from pilot-scale to production-scale.

The tank is equipped with weighing module and the system is equipped with buffer feed pump, which can realize automatic buffer feed.

It can automatically test the water flux and realize constant TMP operation. It can be equipped with flowmeter, conductivity detector, pH detector, UV and other detectors to record the curve in real time.

The layout of each inlet/outlet branches adopts divergent design, which effectively avoids the risk of cross contamination of samples from different branches.

| Names | BPHD Access TFF | ||||

|---|---|---|---|---|---|

| Pump Heads | 0.05~1 L/min | 0.15~3 L/min | 0.5~10 L/min | 1~20 L/min | 1~70 L/min |

| Corresponding Paths | 3/16” | 1/4” | 3/8” | 5/8” | 1+1/4” |

| Pumps | System pump is diaphragm pump,buffer feed pump is peristaltic pump. | ||||

| Inlets | System pump with 4 inlets, buffer feed pump with 2 inlets,or customized | ||||

| Outlets | Retentate port with 2 outlets, permeate port with 2 outlets, or customized | ||||

| UV (optional) | 200~400 nm; fixed single wavelength or variable dual wavelengthes | ||||

| pH (optional) | 0~14 | ||||

| Conductivity (optional) | 0~300 mS/cm / 0~500 mS/cm | ||||

| Flowmeter | Equipped at certain ports according to user requirements | ||||

| Control Modes | Constant TMP, constant pressure, constant flow rate, automatic water flux test | ||||

| Operating Pressure Max. | 4 bar | ||||

| Software | Puriver™ | ||||

Sanitary grade materials, fully meet the requirements of GMP regulations.

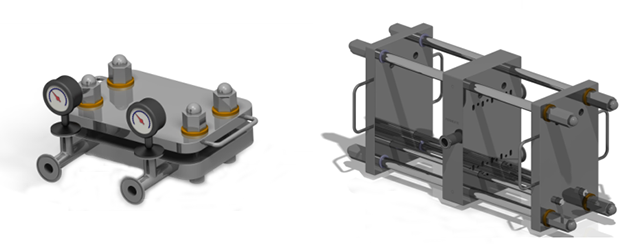

It can be equipped with mechanical pressure gauge and manual diaphragm valves.

It can be matched with various TFF membrane cassettes, such as millipore, sartorius and Pall.

Complete specifications, high-precision polishing of internal wall.

| Names | Descriptions |

|---|---|

| Materials | 316L SS |

| Roughness of Internal Wall | Ra≤0.4 |

| Matched Membrane Caette Brands | Millipore, Sartorius, Pall, etc |

| Accessories | Mechanical pressure gauge / manual diaphragm valves |

| Matched Systems | BPHD ATFF Systems / BPHD STFF Systems |

Diaphragm pump provides power, low shear force and low pulse.

Constant flow rate and constant pressure control can be realized,can be used for clarifying filtration or virus removal filtration.

Can be matched with a variety of sensors, such as flow meter,pressure sensor and turbidimeter.

The design fully meets the requirements of GMP regulations and provides perfect IQ / OQ service.

| Names | CF / VRF 01 | CF / VRF 03 | CF / VRF 10 | CF / VRF 20 |

|---|---|---|---|---|

| Flow Rate | 0.05~1 L/min | 0.15~3 L/min | 0.5~10 L/min | 1~20 L/min |

| Pipe I.D.(mm) | 4 | 6 | 10 | 15 |

| Control Modes | Constant flow rate, constant pressure; pressure alarm can be set | |||

| Optional Sensors | Flow meter, pressure sensor, turbidimeter,etc | |||

| Operating Pressure Max. | 5 bar | |||

| Software | Puriver™ | |||

Dashihe technology Co.,Ltd. reserves the right of final interpretation of this website. The pictures are for reference only.

sales@dashihe.tech (pre-sales consulting) help@dashihe.tech (after-sales consulting)

Company Address: Life Science Park, Changping District, Beijing Hotline: 400-006-8849